1/16/11

I will be making that due diligence run to CRC tomorrow 1/17/11 with JJ in my dually. I am predicting the trans at Carr’s will be done sometime Tuesday afternoon.

I will inform Art that the car will not be driven a single FOOT once it is put on the flatbed at his shop. I want a written GUARANTEE he will stand behind the trans to whomever I sell it. I am done trying to get him and this trans to work.

I will probably have to cut some of the floor pan out and remake that to clearance for the new box.

So be it.

1/18/11

JJ and I visited Craig, and he is all that I had hoped. He has been in biz a LONG time, and is deeply knowledgeable.

I spoke with Art today (no call yesterday from him), and the car is ready. I offered him the trans for $2300, including the GearVendors. He passed.

Allstate Towing will not tow for free, and wants to charge me $177 OVER the $250 tow allotment, and all for 69 miles!

Utter horse crap.

JJ and I will drive down tomorrow and get the car. I will drive DIRECTLY to CRC and get that started.

I spoke with John Meaney at BigStuff and his controller will work with a GM, but not Ford.

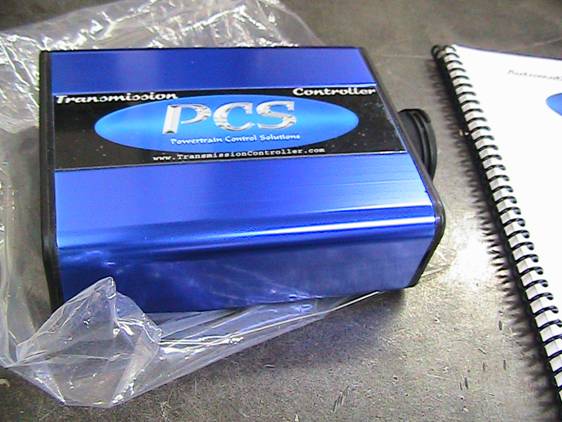

So either a TCI or CompuShift will probably be the controller.

1/19/11

JJ and I drove down to Art Carr today. I paid Carr the remaining $445, and hopped in the car. It shifted badly, hanging in first and second, then washed through 3 and 4. I put $40 of gas in it and JJ and I trucked 70 miles to CRC. I noticed the exhaust seemed more robustly eye-burning in the car and louder than I had remembered. It got WAY more robust as I continued. It was uncorked on the left side, with the double gaskets on the left side flange ahead of the mufflers hanging down.

More idiocy from Carr and CPT. I am SO done there.

Craig drove the car, was unimpressed with the erratic shifting, and said he had done a little more research on E40-D controllers. He did not think TCI makes a controller for the E40-D. We spoke about what he would do to “roid” up the trans, and it’s all in his hands now. I asked him to look around for buyers for the AOD and the GearVendors.

Once he has the units apart and out of the car, I will take pix and renew on Craig’slList and Ebay.

1/28/11

I believe Craig finally got around to pulling the trans and trial fitting the new one. I will talk with him on Monday and see what is shaking.

No Nibbles on the AOD from my Craig’sList listing.

I will go to Ebay now, and a few other venues.

I will shoot pix on Monday.

2/2/11

I have not seen Craig as yet, but may do so tomorrow, to pick up the AOD and GV.

Craig is going to have an aluminum 3” driveshaft made by Coast DriveLine (Mark). It appears no floor cutting is going to be needed. Craig says he wants the ar to be vibration-free at 120 MPH.

I agree.

I reminded Craig about the 3.73 gears.

We MAY need a different flywheel. F/J can balance a new one as needed.

2/14/11

As of last week, Friday actually, Craig had not completed the above list. No new flywheel is needed, but a different torque converter will be required.

Craig is modifying my crossmember to save money and room.

He is still waiting on some trans parts, so has not begun assembly of the unit itself.

I am to contact Mark at Coats DriveLine about the 3” aluminum driveshaft to insure it will in fact be up to the task.

This is taking about three times longer than I expected. I am unworried, although cautiously concerned. There appear to be no daunting mysteries here, just slow going. To date my expenditure has been ZERO. I will be free after Wednesday (finishing a job), and will visit Craig, hand him some dough, and see where it all is.

2/20/11

Tomorrow is booked with a trip to Jay Leno’s garage, so I won’t be making it out to CRC until Tuesday. It has been exactly a month, and I am surprised things have not moved more quickly. I have given Craig ZERO dollars to date, and perhaps that is holding things up. But from here, it appears things are just taking MORE time than expected. Given my shortfall today on the SME job, I can understand how expectations can be confusing.

I will be speaking directly to that point on Tuesday when I hand Craig some dough.

2/21/11

Went to a tour today of Jay Leno’s garage, including some one on one time with Leno himself. REAL nice deal. He owns 4 buildings, has 232 vehicles, 131 of them are cars. He has some amazing diversity, and was busy getting a 1905 White steamer to run for the first time as we were wrapping up the tour. We spent quite some time as they worked it into functionality, with Jay finally driving off in it.

I conversed at length with Bernard and Bob Sales, and hopefully will have occasion to do it again.

I’m looking forward to seeing the Condor tomorrow and just what is happening there.

2/25/11

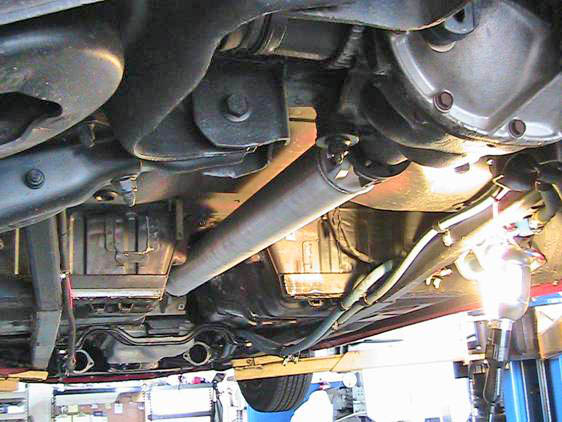

Craig has the empty case in the car, has modified my crossmember by putting a new and different mount on it, and moved it back about 6 inches. He made some mounting tabs of 3/16” flat steel going THROUGH the frame rails (VERY sturdy). He has liberally trimmed the trans case tabs to clear the floor, headers, starter, etc. it looks HUGE in there. Given how everything else in the build was a shoehorn, why should this be different?

We’re still shooting for a 4” aluminum driveshaft.

I handed him $2K in cash, and he says he has everything he needs to go through to completion. He has not ordered the computer (I guess he was waiting on the dough).

3/9/11

Spoke with Craig this afternoon, and some relieving of metal in the underfloor is required. I approved of him modifying the sub-frame girdle with bolt-on tabs and studs. The new ETC is mid-week coming up. So perhaps another week.

JJ and I are EXCITED about stretching the Big Cat’s legs.

No nibbles on the sale of the AOD and GV. And, Duttweiler has STILL not gotten me the repairs invoices on the 427. Gotta get those SOON, as the QMP trial is 4/6/11. I am also waiting to hear from John Beck on his appearance as my witness. I’m getting nervous on these two issues.

3/17/11

Finally got a call from Beck. He closed ProMachine, and is working in a Hot Rod Shop. He still does engines, but the rod shop is his daily thing now.

He won’t come unless there’s a race, so that has me now rescheduling the trial for May 12th, Thursday.

I have perhaps 3 or 4 guys wanting the GearVendor. One guy failed to show today, so I’ll give the go ahead to another fellow in the morning.

I have ONE guy kind of interested in the AOD, who appears not quite ready to make the purchase.

Craig will not be done with the Bird until next week.

3/19/11

Went to CRC yesterday, and Craig is coming along, although EXTREMELY slowly. His overall thinking is good, and he is making it a solidly engineered package. But he is taking MUCH too long here.

One issue was the penetration of the driveshaft through the subfram eopening and existing driveshaft safety loop area. He has cut away the Jay-built turbine-loop muffler openings, and we will replace those with a boltable structure which extends the rectangular tubing at the left and right. In addition, he will mount plates INSIDE the car (behind the backset), so strengthen the area. A future picture will show the existing factory loop bolted back in (the threaded holes more forward), and a framework across the cut-off subframe above.

The trans is HUGE, and the modified crossmember needs one more refinement: a torque limiter. Craig wants to put a bolt down from the mount (look at the upper left bolt on the trans mount), and penetrate through the bottom of the crossmember, with a washer and nut below. This will allow for adjusting the limit to which to engine and trans can torque up to the left, and prevent the system from banging on the floor.

I will put a similar system on the left front of the motor.

This farther-away view shows where the plates will go to the left and right of the driveshaft. Note the size of the shaft at 4”.

Craig also noted the exhaust will need some remaking from the header flanges back, in order to clear the driveshaft and subframe.

The trans has been clearanced, but there remains one area at its upper right which can use a little trimming, as there is only about 1/8” clearance to the floor pan. The trans will tend to move downward, but why start out super close?

Mike came by and picked up the GV, and I gave the money directly to Craig. SO he now has $2800 in cash. It looks like another $3K or so to finish, including the rear gears.

We’re looking at another week here.

3/23/11

I called Craig today and he is WAY slow here. He noted he is losing an employee, referenced some details on the design (we already have heard that MANY times), and promised to start moving on it.

I called him back a little later and said John and I would come out tomorrow and start doing whatever needed attention to move this along, such as the backing plates, welding up the bracketing, etc. He declined at the outset, then said maybe he would call if need be.

Hey, NEED BE is already long past.

Craig is certainly thinking this through, but I have AGAIN been caught in a vendor’s problem and scheduling issues. He has wanted for NOTHING from me, has been paid half the money already. I certainly am not going to take the car out of his shop at this point, but I am going to ramrod his ass daily to get this done.

He wants to test drive the car with the 4.88’s, as he claims the new gears will require 300 miles of break-in. So this puts the whole affair into late next week. This is getting OLD. I already have Montalto for this kind of thing. Of course the difference here is that Craig actually appears anxious and ready to complete.

3/25/11

JJ and I did NOT go out to CRC today, as we just had other stuff to do. I MIGHT go tomorrow, as Craig claimed he would be working this weekend on the project.

3/28/11

JJ and I went to CRC, and Craig has fabbed the sub-frame xover piece, set 3 bolts on each side, used no plates on the footwell/floor pan area, has completed the shifter mechanism and tie-in with correct detents, and plans on stacking the trans case tomorrow. He feels he will be test-driving on Friday. This presumes he can get his local muffler guy to makes some pipe alterations.

Craig explained the thinking on breaking in the gears (factory gears come polished, after-markets do not) for 300 miles.

So we’re looking for Tuesday or Wednesday, another week from now.

Oh boy.

3/31/11

Yeah, really OH BOY. The trans is NOT in the car, and Craig is apologetic, but not remorseful. He has really disappointed on the timeframe here. So it is looking like NEXT weekend for the car. I might get two days of driving before my knee replacement.

4/4/11

Craig intends to get the trans in today and fire it up tomorrow. He is raising the driver’s seat 3”,

mounting the trans computer under the seat,

and doing some work on the exhaust once the unit is in and functioning. It still looks like Friday for this to be in my possession. I will call late this afternoon and see how he has progressed.

4/5/11

Craig did not get the trans in as of this afternoon at 5:01PM, and the muffler guy is hurt, so Craig is looking for someone else. The delays continue. He claims to be working on the seat right now.

The under floor is cleaned and sprayed.

Good.

PREDICTION: NOT ready by Friday.

4/7/11

Talked with Craig today, and they are JUST now getting the trans in. He intends to fire the car up tomorrow, without the computer, and poke over a block away to the muffler guy for the exhaust completion. So perhaps on Monday he will have the car back, Tuesday might have the seats done, and Wednesday might have the computer mounted and programmed. These are my estimates. Best case scenario now looks like next weekend including changing the rear end gears. There is a possibility my knee surgery might be postponed, so I might actually get to drive it before the knee replacement.

Oh boy.

4/18/11

I DID sit in it today, with the seat elevated, although not completed, and it feels fine. The trans is in, and the computer goes in tomorrow. The exhaust is finished and looks TITS. The whole underside of the car now looks MASSIVELY engineered and King Kong strong. Both Kelly and JJ were mightily impressed. Craig will drive it again tomorrow, this time on the computer, and get it programmed. He claims the left battery loses charge in about 30 minutes after running the car. I suspect they are leaving something on. Otherwise, the NEW Duralast will join a long succession of prior dead batteries at AutoZone.

I pressed Craig to have it done for Friday so we )he and I) could christen it at Bob’s.

I am going out to Duttweiler’s tomorrow to get my engine receipts and a gear ratio opinion from Kenny.

Craig will be hooking up TWO ELECTRONIC CONTROL SWITCHES FOR THE TRANS: one to lock and unlock the converter, worth about 300 RPM, and the other to engage overdrive. I am under the impression this will shift automatically into OD, although I am not sure about this. Anyway, we are closing in on it.

4/19/11

Saw Kenny today, got his decision on the rear end ratio, and more about the rear end, and the paperwork for QMP’s trial. KD said the IRS would certainly fail for several reasons. Sidestepping his solid logic, the issue is now to find someone to fabricate a 9’ REAR. i Called Mark at Coast DriveLine, and he in turn referred me to Larry Bryant, a world-class fabricator.

The short of it is that Larry is going to see the car, and will report to me tomorrow morning, Estimated cost: $8000.

I will sell some of the IRS stuff off, so whatever remains is the actual cost.

This SHOULD put the final steel beam in the system of indestructibility. I am clear about it, agree, and just want it done.

4/20/11

It took Larry until today, this afternoon, a day later, to see the car. Craig is not done. Perhaps tomorrow Craig will have the computer wiring connected, final mounted, and the car running. He must obtain the two rocker switches at Pep Boys for the torque converter and OD functions. I did not hear back from Bryant.

I’ll give it until tomorrow, and then probably have to look around, as this would indicate the same old “fuck you” rather than” thank you” for the work.

Stereo Steve is interested in everything I take off the car for his 90 SC. He will need the trans shortly, and I have a killer deal for him at $1500 with the torque converter. A straight bolt-in for him. I will trade him some electronics work for part of the cost. Steve also is drooling for the 4.88 rear. I will sell the WHOLE thing, from hub to hub including sway bar, Tokiko shocks, Eibach springs, ABS counters, A-arms, brand new 4.88 posi center section….ALL of it for about a grand.

Newest problem: how to get wide tires for 16” rims.

4/21/11

Larry called today and apologized for being hard to reach. He said he was burned from 18 months of straight work, and needed a day away from the phone.Good enough.

He said he saw the car, and said DO NOT go 9” straight axle, But he DID saygo 9” IRS from Shelby. Roided up exterior parts are readily available. This will not be much cheaper in the long run, but will retain the streetability and comfort of the stock springs, sway bar, etc.

Larry feels we CAN take the SAW blade centers and graft them into 17 or 18 inch rings, and recommends my same guy at JK fabrications.

4/23/11

I have become sensitive to prompt communications, as most of my processes in this and other cars is just hugely ONG and drawn-out, delayed-ridden, snake-bitten, venom-spittin’ experiences.

Larry Bruant has not gotten started well in that regard. He took two days to get to me (he claimed he HAD to get away from the phone), and now again he was to have called me yesterday, and did not.

I pretty much know the info on the Shelby 9”-based center section IRS, but do not know what the exact specs are, how much, etc.

And, having him respond quickly allays the I’ll-be-lost-in-the-shuffle triple-the-time and double-the-cost deal.

So I’m patiently, if not happily, waiting for that hungry-

for-business call from him.

He appears not to be all that hungry.

Bottom line: probably good, short line: troubling.

Craig failed to make our Friday final deadline. It looks like Monday or so now, There has been a half a month of Mondays already.

I made a “stat” visit to Craig early Friday morning to confirm some electrical routings and sources, and forgotten take my extra three gauges and A-pillar gauge pod for him.

I’ll call today, Saturday, and if he is in will take those gauges.

I have the funding RIGHT NOW, and I need action taken RIGHT NOW.

Besides, 22 years is ENOUGH already on finishing this car.

4/23/11

No call from Larry, nor from Craig. I was to have called Craig, but it just got late on Friday. Saturday, today, no answer at the shop.

4/25/11

At 5:04 PM today Craig basically said he had been standing at the car all day long, but answering the phone and running his business. It sounds like tomorrow or Wednesday. My guess is Wednesday.

If he had said this would be a sometimes thing, spare time, in-between customers, etc. at the outset, perhaps I would still have said yes.

Unfortunately, this has been thrust upon me, and I have had little choice as the deadline has been sliding back and back and back, other than jerk it away, which would likely not have produced a quicker result.

Now that I am working on a new guy for fabrication on the rear end, I am pushing Larry Bryant for answers and commitment, and that is not going well, either.

Randy pointed out that his criteria are: price, quality, time. Craig is surely not doing well on the time factor at all.

4/27/11

I left LB a short message, “just in case you lost my phone #...”.

Similarly, I will not be calling CRC. I will wait until he calls me to tell me it’s done and ready for pickup.

Bob Dale from B/E called me yesterday, VERY good timing, as I was about to call him.

He will call me Monday and we’ll go over my projects then.

No call from Craig or LB. Probably just going to go the way of B/E.

Whatever.

There are lots of guys out there who can weld, design, and fabricate. I jut CANNOT wait and wait and wait anymore.

4/29/11

4:33PM

No call from CRC.

No call from Larry Bryant.

I had some separation anxiety years ago when I restructured my relationship with my dad, after our “divorce.” It took some adjusting to keep quiet and space between us. This is the case here. It goes against my “make it happen” and “communicate thoroughly” ethics to walk away for a while. It has done me no good (has not produced finished product results) to keep calling these guys, so the real decision has been to abandon them as a source of support in these projects. AS IN THE CASE OF ORGAN BOB, SOMETIMES THERE IS ONLY ONE GUY IN TOWN, BOB FOR THE ORGAN IS THE GUY, AND IT IS MADDENING.

As for LB I’ll just miss his expertise altogether, and with Craig I won’t do much repeating of this NEAR-INFINITE TIME FRAME process again with him. I am undecided about letting him do the Impala. I don’t have a real pressing agenda on the Impala, but I certainly don’t want a second helping of this interminable waiting game, either.

So on to B/E come Monday morning.

5/2/11

B/E went well, and they have a guy, John, who they say is good for the rear end work. We’ll talk more later in the week when they go with me to Montalto’s to look at the KK.

I hope to have the Bird back before then. No call from Craig, of course.

5/3/11

Again, Craigless today.

5/4/11

Finally called Craig. Power Train Control Solutions sent wrong year computer trans control program (96) versus 92-94 actual. Craig took over a week troubleshooting his own wiring, etc. to insure problem was not in his work. I informed him we are at one week short of 4 months. Craig says disc should be here today or tomorrow HOW ABOUT OVERNIGHT SHIPPING?

GET IT DONE.

5/6/11

So it’s Friday night about 6:30 PM, and Craig did not finish. I talked to him yesterday and he did get the disc, and was doing a little rewiring and supposedly programming it. NOT DONE. Man oh man.

5/9/11

Called a half hour ago, no call back. There obviously has to be a way of dealing with tardiness (what an incredibly polite word for FOUR months of BS). Clearly, I am NOT employing the proper protocols, as I have WAY more than a fair share of this happening in my life.

5/10/11

I reached Craig today and he claims the delay had to do with a faulty wiring loom as sent to him with the computer, AND the wrong disc. He claims the car works well now. Interestingly, he did NOT call me to say so, I had to chase him down.

Ridiculous.

He says the alarm screws things up when the car is NOT running, but the key is on as in programming the computer, etc. He also claims it runs badly when it gets warm. Again, new story for me.

We’ll test drive it tomorrow before noon.

5/11/11

JJ and I went out, test drove the car (AFTER immediately getting fuel), and felt it was working OK. It was delicious to be able to squeeze it above 40 MPH. We got on the freeway, and the RPM’s seemed WAY too high. I got back on the surface streets, and flipped the OVERDRIVE switch the OTHER way, and bingo, lower revs. So Craig had the switch backwards. NO MATTER. The lockup switch was said to be inoperative right now. So we took off, arranging to bring the Impala in on Monday, with a maximum 4-day window, after which time Craig agreed he would start owing me money.

I made it clear that every day under 4 days would get him his money faster, and he agreed.

As we got on Gault coming home, the trans felt like it was lugging down on the 4-3 downshift, a sign of torque converter lockup.

When we went to move it later, it died immediately in DRIVE. Short story, I found Reverse and LOW did not stall. It is locking up on its own. NO BUENO. I drove it down the street and I can operate it manually in LOW then shift up, but must shift down or stall.

So back out it goes tomorrow.

OMG!!

5/12/11

Got in this morning and ONLY 2nd gear is available in forward. Took the car to AL and Ed’s to have the alarm removed, and possibly get the stereo powered up.

Went to court on QMP and LOST!!!

Utterly unbelievable.

What a catastrophic waste of 5 years, thousands of dollars, and hundreds and hundreds of hours of time and effort.

So there’s $7500 of what I thought would be coming that is NOT coming.

WHEW!!!!!

5/13/11

In a happy turn of events, Al and Ed’s removed the alarm and did not charge me. We talked about a new door popper. Jeremiahnoted they sell Clifford, but that Viper and others are all made by the same company. They COULD order a Viper, and it MIGHT fit the old plug. If so, no $500 rewire job. Otherwise, big $ to clean up the rat’s nest under the dash and put in a new door popper.

The trans works FINE. NO problems at this point!

HOORAY!!

JJ did some wacing on the cars, both Impala and Condor, and did some great cleanup on the wheels and trim. Check it out:

Of course he and I are DATH to our heads under the rack. JJ did it TWICE in a couple of minutes:

I’m going to paint his hard hat pink.

5/15/11

We went to Bob’s tonight. The car ran perfectly, the crowds were plenty, it presented well. We had a good time.

I suspect the master on-off switch on the dash has a loose connection. I will check it today, perhaps requiring I lift out the console.

I spoke with Rob Anderson a couple of times, and reminded him that he wanted the trans working in the Bird before he would look at the hifi. It is now working, and he is too busy.

Just more moving on in life……

Stereo Steve is coming over today and will be trading me electrical snooping for my old 30-foot awning system.

5/20/11

The dash switch WAS bad, as the crimp connections as done by CRC were loose. I soldered new ones, and it works fine now.

The fans not working was a two-fold issue:

1-both the manual switch 9grounding) and the computer were not triggering the fans. After some bypassing with direct wiring, etc., I found that a jumper on the right cowl buss was loose, and not powering up the rest of the buss. That fixed it.

2-I found that the HOT lead to the two fan relays would power them up (it is there as an alternate way of switching them on) and that was how I found the buss not working on all pins.

Steve has determined that all three amps are dead. He used his own bass amp, and the woofers worked. He found one Monolithic amp not functioning, and the other died in a few minutes of running.

So I have placed a call the Greg at Monolithic, to see if I will have hi repair these or just buy new, or what.

The lousy running appears to have been somewhat cured by John and me fiddling with the plug wires. I tie-wrapped #8 up and away from any header contact. It seems to run fine now.

So off to Bob’s we go tonight.

I contacted Mike at Maeco in Reseda (he built an engine for me 25 years ago), and we’re talking about 3.40’s for the rear end. I did not hear back and have left him a message this afternoon.

I got in touch with Jim at Bones Fab in Camarillo, and he is willing to look at the car and test the BigStuff. My main concern was the ragged running. I may invest in a new set of wires first, and see how that goes. But I still need someone to be able to tune and troubleshoot the system, show me the ropes, and guide me into a laptop universe.

5/20/11

JJ and I met Dan at Bob’s. All went well. The car ran nicely, and for the first time I was able to use the toggle switch on the console to manually downshift to third. There may be some adjustments to shifting necessary once the easier rear end gears are installed. For now, it downshifts a little radically on kickdown, going into second. So some allowance for letting it lug must be introduced. It does, after all, have 768 # of torque!

While under the car I noticed the left subframe bolt was NOT tightening up, and the 1” steel spacer placed there in 1993 was rattling. So I welded them both.

5/21/11

Went to Santa Clarita to the retirement home show. Nice folks, and a REAL nice courtyard under a HUGE oak tree, and plenty of cars.

The car ran well, except it started “burbling” close to the destination. It ran its usual “burble at idle” on the way back. Sure want to correct that.

The puke tank has migrated right up to the AC compressor pulley. I need to rotate the puke tank mounting by shimming it slightly. This is another of those “break-in” items.

5/23/11

MORE break-ins:

The starter started grinding a lot when JJ and I stopped at CRC to pick up the Impala. It took LOTS of doing to finally get it started, and I drove straight here, put it up on the newly cleaned front rack, and pulled the starter. The flywheel is ground at an angle on the leading edge in many places. The starter itself looks pretty good. It is a Hi-Torque unit. I will take it tomorrow to Whittier and have Monty look it over on the spot. It appears I will have to replace the fywheel, meaning the trans must come out. I called Craig who said it would be no big deal, now that all the many iterations of refinements and mountings and exhaust have been done. Good for him.

I will likely tow it out there, after I talk to Randy and Hi-Torque.

6/4/11

The replaced 6-rib belt is now 4-ribs. It appears perhaps the lower alternator is back about a ¼” and is eating off the ribs.

I will check it tomorrow.

It is scheduled to go to Bones’ for the rear end on Monday. Gotta get that belt right first.

6/10/11

Got the car back from Bones with the 3.54’s.

EXCELLENT!

Cost: $1235.

Gas savings: PRICELESS.

It drives quietly, and easily at about 2250 RPM at 65 MPH.

I see one idler which can come out about 1/8”, the lower one.

I am NOT taking the Bird to Bob’s tonight, rather I taking the Impala, which has a more urgent need to be exposed for sale.

I will be driving the Condor without the hood for next week, then will give it to Nick to finish the body. Nick is repainting the hood. We found two interference points on the motor, one of which might be solvable, the bulb-hub 4” sleeve between the intake pipes. We’ll try going back to smooth, and see if it holds.

6/14/11

Kelly and JJ and I worked the sleeve today, and got it in place. This requires removing several pieces, but short story it is done and appears to be holding so far. I MAY have to raise the elbow slightly to silence some interference with the fender well.

We tried putting a breather tube breather on the left valve cover, and piping it into the blower bypass line. NO suction, just pressure, so that didn’t work. So I extended that breather line past the back of the driver’s door, and we’ll see how the smoking situation works now. This was about a $100 NO work attempt. I might eventually try a little vacuum pump, although this SHOULD do the trick for now.

I changed the offset on the lower idler and the belt sees to be running OK now, although it still squeaks at start up.

JJ drove the car and is AMAZED at how civilized it feels with the easier gears.

I went to Nick’s last night and we trial-fitted the hood. Nick is just going to paint it as-is now that he has floated and blocked it. He is also going to reshoot the front end from the doors forward. Good thing, as I scratched the front of the bumper by rolling in about 1” too far on the lift, and nicked the front of the KK grille with my bumper.

6/17/11

Got the car back ALMOST with AC. Morgan didn’t complete the wiring. I need to connect a hot wire from the AC system to a relay to start the fans whenever the AC is turned on. This hot wire is turned on by the dash control, and also needs to be run to the hot side of the compressor. I will cut the wire BEFORE the diodes, and connect that gray hot. That should do it for running the AC.

However, there MAY be a hood interference problem with the Schraeder valve (like a tire valve, but for Freon), which sticks UP from the front of the compressor. This valve was NOT in place earlier. This might require pulling out that valve and putting in some 90-degree fitting, and RECHARGING the system. This is MONEY.

I let John drive it home, and he gave me a hug with tears in his eyes when we got home. He is SO impressed with EVERYTHING about the car. I got to see it for about 10 miles from outside, hear it, watch it get sideways and snarl. I LOVED it. This car is REALLY good-looking, and rare.

What a KILLER sleeper!

You suspect NOTHING from outside except at idle.

6/19/11

Aside form the belt squeak, and what I detect as an bit of a miss, the car drives great. I completed the AC wiring, relay, etc., and that works nicely. The fans come on whenever the AC is triggered, as they should. This coming week is supposed to see summer weather (I HATE it), but the Bird will be at Nick’s getting prettified again. We will find out tomorrow if the hood clears the valve.

I may try replacing the serpentine belt again, and tighten it more than previously. It is shredding the inside edge. I have adjusted the idler, and all seems pretty much right on. I will probably install a welded and fabricated bracket tomorrow to stiffen the upper alternator bracketing (and AC mounting).

The car oddly seemed to be running out of fuel under full throttle yesterday on the freeway on ramp, so I refilled the tank, putting in about 12 gallons. It should have had plenty of fuel with a half tank.

6/20/11

Two of the fans (the left up and down) quit today in Burbank, causing it to run quite hot. If I maintained over 60 on the freeway it brought the temp down near middle, otherwise, near top. I still need to see why one relay is failing. I’ll replace it tomorrow when LC is open, and check function again. I CAN get both fan packs working if I put 12 volts directly to the relays with the spare wire I ran. This would have been the emergency fix for that moment, and I will put a clip on that wire to allow for that in the future.

There is still some gas smell. And, the odd burbling off minimum throttle. But it hauls ASS, and otherwise drives nicely.

The AC is not functioning well. ON MAX it is just blowing inside itself, and on normal, there is perhaps half the air volume of old. This was a KILLER system in its original form. There should be no difference, notwithstanding the change to R-134.

I’ll get it back to Morgan tomorrow afternoon, and see what we can find. I believe there is an electrical or vacuum actuation not occurring.

6/26/11

The AC on its own seems to be doing better. Perhaps there was a moment of bad function overlap with the non-working two fans out of four. Whatever, it still appears to be blowing inside the box, but is cold, and works fairly, but not brilliantly yet.

The belt squeak needs a little more tension on the lower tensioner. The upper adjustable tensioner is maxed out. So I need to see if we can go further on the bottom. The alternator appears to have cocked very slightly inward due to the tension of the belt, so it appears a strong-back rib will be needed.

Nick has been occupied with his ex-wife from Boston (one of four ex-wives) visiting, so he wants the car tomorrow or Tuesday.

I would like to get the A-pillar pod of instruments in place so I know what is really going on with oil pressure, temp, and charging.

6/27/11

By removing the radiator hose connection at the thermostat housing, and a pair of holding brackets, I accessed the lower adjuster, ran it up pretty close to max, and backed the top adjuster a few threads. No belt squeak.

7/4/11

The car is running OK, although the oddity of loss of fuel pickup at about a half tank is disappointing. But the car otherwise runs fine, has the odd miss-sound at minimum throttle, is remaining cool, and the AC works mostly, but not on full. I will get that over to Morgan in the next couple of days.

Nick is scheduled to take the car tomorrow, Tuesday 7/5 in for the paint renewal.

There still is some kind of fuel/exhaust anomaly, although greatly reduced. Just a little odor now and then.

The rear end continues to spray goop from the CV boots. Bones will need to look that over, as he should have cured that with the rear end rebuild.

And the sway bar does hit the front pan drain plug despite the numerous grindings, changes, etc. done there. Removing the engine oil pan in place is impossible, and lifting the motor is also just onerous. I need to find a way to modify the pan in place. Randy says it is impossible to weld a new bung in place as the welding heat will draw oil to the weld.