Hemi Cayne Page 2 9/20/09 to 10/13/09

Back to page 1

9/20/09

I

called around to several Mopar guys looking for a rear sump pan, but

nothing solid as yet has turned up. Randy came by Friday, and we spent

some time on the mounts. Randy suggested some changes (good ideas), so I

modified them. We decided to do the following:

Move the left mount up and back, requiring trimming a lot off the actual

engine plate mount, and re-drilling some new mounting holes. This

relocation also allows me to get the long pivot bolt in without hitting

the oil filter area.

Modifying the outer portion of the mount which has the bushing by

relieving the bottom portion to clear the crossmember, and removing the

welded-in mounting bolts.

The passenger side required only the second portion of modification.

The mounts are waiting for a proper pan to allow for an approximately

1.5” thick mounting block to be fitted (tapered to the back because of

the downward to the rear engine angle), drilled and tapped, bolted to

the outer portion of the mounts, and welded to the crossmember. I will

have H&R Machine do this milling operation. This will all appear totally

seamless once done, and the mounts will look unmolested. And I get to

keep the fuel pump in its stock location.

Miranda did not make it over to look at completing the interior. Perhaps

tomorrow.

The speedo cable does not match the 727 trans, so some adaptation will

be required there.

I

also need to get a power booster and master cylinder.

Chris, one of the Rodfathers, again failed to show for the second time

to view the car. He had expressed interest over 2 months ago in the

project, did so again a week ago Monday, and again last Friday night. He

just does not get here, and I don’t have his phone #.

I

am also going to rethink one more time where to mount the trans control.

But I do like the left hand configuration. Some of the early Mopars had

it in the center of the dash. There is no really convenient place in the

middle of the dash on this car.

I

am going to get that new trunk pan in tomorrow, maybe install the new

gas tank, and perhaps pull the bumpers off the #2 car and fit them up.

Anything I can do to make the car more finished has to help.

I

will start ebay looking for some parts, but as noted ad nauseum above, I

have ZERO dough to buy anything, save the pan (and only if I am REALLY

careful not to run out of money before the next rent check comes in). I

am anxious to go through the piles of boxed parts on the other car and

see just what I can start fitting. Probably nothing cosmetic until I can

afford the bodywork and primer. Randy suggested I have the primer done

in satin black, as in a new rat-rod/industrial look. Good idea.

I

still owe Mark $5000 on the engine deal, so I have to be REAL careful

here or I’ll just be giving the install and the car away.

9/22/09

I

did not get to the trunk pan, as I have been on my roof for two days

cleaning gutters, etc. HUGE work.

Tomorrow will be trunk pan welding day. It also should be the oil pan

arrival day as well, which would free me to get over the H&R Machine and

get the mount pads machined.

9/23/09

The pan arrived today. WRONG pan. I am sending it back, and have ordered

the hopefully proper pan from Summit for a LOT more dough. It should

arrive tomorrow or Friday from Nevada. The pickup will be shipped

directly from Milodon, and should arrive shortly as well.

As noted yesterday, I have spent the last few days doing house chores,

including moving some #2 Biscayne stuff around outside in the driveway

(which blocks moving out the Regal. This Regal relocation is required

for the pan work). I will get into that car when the sun sets (it’s 2:57

PM and 102 out there right now). I just MIGHT get that trunk pan started

today.

9/24/09

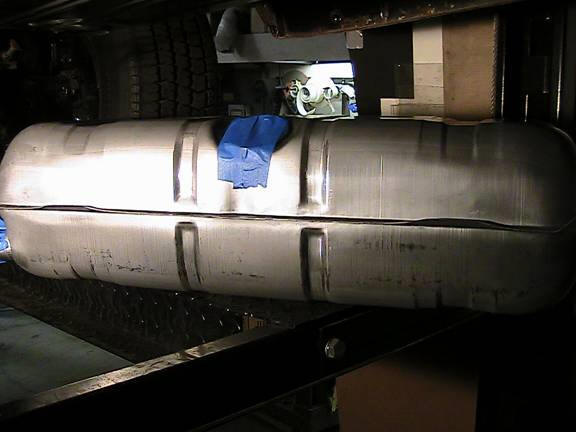

I

DID get the trunk pan in, and am about to mount the new gas tank.

The old tank looked fine, but the smell of varnish/gasoline says it

needed cleaning out. I did so, and have it set aside for the #2 car if

needed. A new fuel line will be needed for the Hemi. I also will need a

new fuel level sending unit/float, as the old one looks pretty crummy.

Meanwhile, here are two shots of the front mounts without the oil pan.

If you look closely you can make out the gap where I will machine some

spacers to receive the mounts. This first shot is the left (driver’s

side) mount, and the end of the steering box shaft is at the bottom. The

partly primered mount arm is extending off its pivot behind the oil

filter and pressure regulator adjustment nut. The left upper A-arm shaft

is just above the mount arm here.

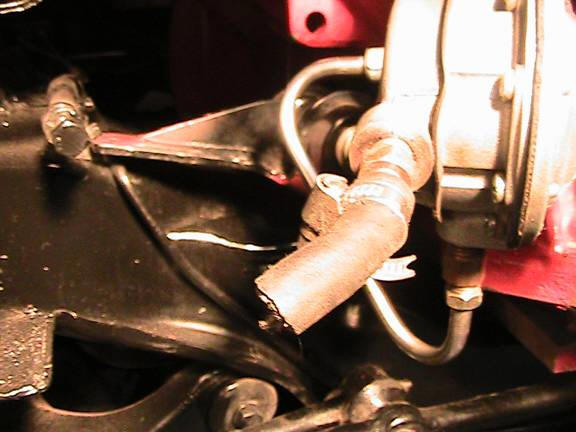

This next one is the right mount, nestled in behind the (for the moment)

detached fuel pump. The pivot bolt for the mount is serviceable, a good

thing. It is barely noticeable in the fuel line loop area. The mount arm

on this side is laying on the right side brake line. There will be about

1.5” in between those two points when finished, filled with the machined

spacer block.

9/25/09

The correct pan and pickup arrived today. The pickup is SOOOOOOOO long I

have to pull the engine OUT of the car to install it! I am mocking up

the foam spacers for the mounts now. I’ll do a couple of iterations and

get them really close, then go to Al on Monday for some machined steel

blocks.

I

am just welding the retainers for the gas tank now, having gotten some

fresh bolts for the straps, and a pair of 6” long bolts for the rear

trans mount (to allow me to tilt the engine up. I may have already

pulled the threads out of one side of the trans case/mount.

9/26/09

Spent a couple of hours today mocking up the foam mount pads. I think

I’ve got it close enough. I’ll visit Al Monday and see what he can mill

up for me.

I

don’t know if the engine will settle once it is bolted in. If so, then

I’ll have to come up with some shims and do a little oval work on the

mount holes.

I

put some extenders on the bolts for the gas tank, and got it pulled up.

It will have to come down later for fuel line, sending unit, and

connection to the filler neck. But for now it is up. I will probably

repipe the front brake lines given the welding to do on the crossmember,

and a newer master cylinder to come.

9/29/09

Randy spent the day here yesterday, making some VERY cogent

observations, and saving my butt from a costly fuel pump mistake. How

did I get this far without him helping? I’m serious about that. I DID

manage to slice my left index finger on the pan, however, with NO help.

I cut the center back half of the crossmember out to allow the motor to

slide in with the pan on, and will have Angel do some welding in that

area tomorrow. I can do it, but he wants to help, needs some dough, and

we can work it out.

Roy was here today, and we spent most of the day chasing Condor parts,

and did little on the HEMI-Cayne.

Al at H&R passed on machining the mount blocks, so I made another

pattern in paper and will start cutting out pieces of ¼” steel tomorrow

to have Angel weld up the pads. I also found some patch panels in the #2

car for the rear fender lips, and I MIGHT have Angel install those as

well. He has some experience doing this for some custom car shops.

I

also found a second u-joint for the steering column. Randy and I did a

little mocking up and it appears I can use the Ididit column and still

go UNDER the left A-arm, and clear the potential header location. A

shorty (16”) column to replace that one for the KiloKub is almost $500.

OUCH!

I

thought I had pulled threads on the trans case. It turns out I had

inserted a smaller diameter bolt (3/8” instead of 7/16”), so things

MIGHT be OK there. The engine and trans slipped back in with the rear

crossmember in place. I still need to make up an approximately 3” tall

spacer between the trans and crossmember. For now I will look for some

Grainger doughnuts like I used on the Duramax engine front mounts. I MAY

need to put a sleeve in them for the 7/16” bolts, as I seem to recall

those mounts were ½” diameter. I’ll check tomorrow.

In searching for rear end components it appears a center section is

closer to a thousand bucks, and axles about $330. I may not need any

beefier axles. I’ll need to search for some cheaper deal on the rear

end.

Disc brakes are also close to $1K for all four wheels. I already have

brand new wheel cylinders for the drum brakes. We’ll see how that all

plays out down the line. I found a black 7” master and chromed booster

for $200 on Summit. Gotta wait on buying it, but that looks real good to

me.

9/30/09

Angel joined me today and will again tomorrow for the making of the

mounts. I did more pattern-making, this time out of paper, and he did

most of the cutting grinding, and welding. I did the pattern-making

fitting (DOZENS of in and outs of the mounts), clean-up, getting tools

in place, and some fine tuning.

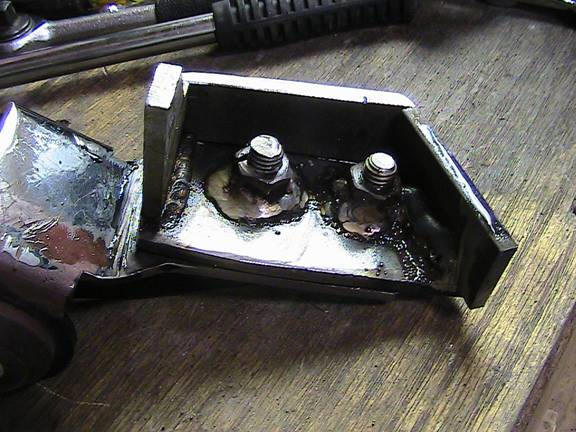

Here’s the right mount partially made:

Angel expressed amazement at the pattern technique. The pix below show

the left mount tacked in without the engine in the way. We tacked it in

place, one piece at a time, until it was solid enough to hold the motor,

then leveled the engine and went about doing the right (passenger) side

mount in similar fashion. This was ALL day with two guys working

non-stop We’ll have another whole day tomorrow finishing the tack-in of

the right side, pulling the motor and finish-welding of the mounts.

I

also located the other u-joint for the Ididit column, and it appears

getting the steering linked in will be relatively easy although some

stand for the upper joint will likely be needed.

I

showed Angel some rust repair areas, and we’ll get into those down the

line. For now, it is the major welding we are addressing.

10/1/09

We removed the engine and trans to allow for more complete welding of

the mount pads. Each mount required 5 separate (and distinct from one

another) pieces, laboriously fit and re-fit until correct. This is all

cut out of ¼” steel.

Then we

need to box in the cutout in the crossmember (made to clear the oil pan

on install and removal). Without the cutout in the crossmember getting

the motor in and out would be nearly impossible, notwithstanding how

close the tolerances were to actually slipping it in. That’s what is

maddening. It is SO close but you gotta do what you gotta do. I don’t

know as yet if I can actually get the pan off the motor after it is in,

even with raising the engine up 5 inches or so in front. We shall see.

10/1/09

Angel and I finished the mounts, and they look great.

I

am now working on finishing the boxing of the crossmember. It looks VERY

strong and trick.

The top of the picture is toward the rear of the car. The two V-ribs

will tie the floor of the crossmember to the box, when the plate is

welded in as the “floor” of the box. The left and right sides and the

piece going closest to you will all go to the floor, and tie it in

further. Then that floor will tie it ALL together. This is now the

strongest part of the crossmember.

Here is the floor welded in. This is NOT TIG-welding, although it looks

like it.

The four holes are the anchors points which weld the floor of the box to

those ribs below. The three surrounding sides (all ¼” steel) go down to

the bottom of the crossmember. You can now see how strong this area is.

We will endeavor to get the engine and trans back in the car and see

just how they bolt back up. They looked great before pulling them out.

We also need to build up the rear trans mount with the aforementioned

Grainger’s doughnuts. I have ZERO dough (well actually $4.54 TOTAL). My

front renter is late with he payment, so I am STUCK.

10/2/09

The renter did NOT show. So I managed to scrounge $6 from a recycling

center for a trash can full of bottles and cans, bringing my TOTAL cash

on hand to $11. And ate lunch at home. Angel and I finished the mounts,

ground everything smooth, primed and painted the area:

and set the motor back in. Here are some more shots of the state of

affairs. This is the right side mount with the engine back in place.

The boxed area is really excellent looking, and the welds are primo.

Below is a shot of the left (driver’s side) mount. The pink is primer,

not bondo.

It took a little working to get the bolts to line up, but really not too

bad. We shortened the bolts, and I slightly opened the holes in the

Schumacher mounts.

The car is off the rack, and looks kinda cool.

I’d love to get to the bodywork.

I’d love to finish the whole car.

I’d REALLY love to have someone buy the project RIGHT now.

10/3/09

No pix yet, but we had a busy day. Angel and I mounted the front of the

beam, after Angel blow-torched it off. I nailed a 2x6 between two NEW

152” long studs, so now the engine hoist is more secure. I will do some

metal brackets under the 2x6 for added protection, and drill some screws

through the beam into the header to hold it in place. Once the MDF goes

on the wall, the beam will be further locked in place.

Angel hounded me into tearing OUT the new trunk pan so he could do a

better job of cleaning up the mounting. Actually, he got completely

sidetracked and ended up blowing out dirt and sand and wire-wheeling off

rust and paint in the trunk and UNDER the car to the rear wheels. This

necessitated blowing out the garage a DOZEN (literally) times with a

leaf blower, vacuuming numerous times, and washing the place down.

Tomorrow Angel will primer the underside and remount the trunk pan. We

MAY put the gas tank up, or wait for the filler neck assembly, sender,

and some wiring mods.

10/4/09

All was going well, until I got home today, and Angel had cleaned the

upper area of the trunk, welded the trunk pan back in, and made the

corner patches. This was 6 hours of work. I asked if it took him 5 hours

to weld in the pan, and he said yes. I simply said, “Wow.” No

criticism, just the single word.

Angel then did one of his (at this point in history) fairly predictable

hissy fits, started complaining about how he was to get paid, got up on

his “A” horse and changed the rules on his “time”. It is stunning how he

manages to do this combative stuff. He invents criticism where there is

none, and goes BALLISTIC on his own response to his OWN stuff! So this

has happened enough, and I don’t want any more of this in my life.

He is now DONE with the project.

OK, then.

I

bought a couple of cans of Satin Black primer, and sprayed the right

front fender and door area just for a look.

I

also got two more 6” bolts for the trans (remember I bent these lifting

the front of the motor a little while ago). These are temporary, as I

really need grade 8 bolts at 5.5”. I still need to go to Grainger’s for

the doughnut mount pads.

I’ll finish grinding the welds around the pan, do some caulking in the

corners of the trunk, and apply some primer to the area.

I

MIGHT take the wire wheel to the interior of the car and clean it up and

get it primered. I have a can of rust locker to use on the interior

metal prior to upholstery.

I

might also kick the front window out, and open that metal to some

correction.

I

cannot take the car to Ken’s guy for bodywork until I have cash. It

appears at this rate that JJ and I will just do all the body prep and

repairs.

I

can work on the steering column, perhaps notch in the shifter box at the

left side of the dash, and trial fit a Duramax radiator in the core

support.

10/5/09

Randy dropped by today, and as usual made some cogent observations and

spurred me to action in a few areas. One of these was to remove the

motor (actually just disconnect the mounts and lift it about a foot),

and try fitting some TTI headers. They really don’t fit. So we dropped

it back down, clearanced a portion of the left side mount, and with some

effort got the mounts to line back up. We spent some time on the

computer looking for headers, and I called Sanderson. They appear to be

the only ones with a block hugger header for the 426 Hemi, and offer a

return policy if they don’t fit. So I will, when money permits, order a

set, trial fit them, and if they work, return them for a ceramic-coated

set.

Randy thought I should put the windage tray in the motor, as I had

removed it when fitting the new pan. This is not critical in any way but

I will likely do so. I need some new gaskets, as it appears Mark ran the

pan bolts a wee bit tight and one of the two gaskets had some splitting

at some holes.

I

tried a Duramax HUGE radiator-way too big. It won’t fit between the

fenders, and is too high. We also did some Internet hunting and found a

31 x 17 unit reasonably priced around $180 that looks like the ticket.

It will require some core support mods, no big deal.

I

will use the RF fender off the #2 car for less bodywork.

We set the hood on and by golly it FITS! Clears the motor and

everything! The hood scoop that came with this hood works perfectly over

the carburetor, including an old 13” Tbird chrome air cleaner I had

here. That is a lovely deal right there.

I

will investigate a rubber mat for the trunk and pan, and if findable

(Randy assures me it is), I’ll just shoot some primer on the whole area

and leave it at that. John Jarnagin has agreed to come on board and

start working the remainder of the paint and bodywork. He and I work

wonderfully together, and this will be a pleasant turn of events. We’ll

get started either tomorrow or Wednesday, depending on how a small job

view goes in the morning.

10/6/09

We did not get back until later in the day after completing the job, and

JJ and I spent a couple of hours on the trunk. I welded in three

patches, he ground them down, and I primered the area. JJ will bring

some bondo and 100# paper for the DA, and we’ll start removing the

surface rust from the body. I did a little on the hood area with the DA

using 220#-waste of time. I did some with a flap disc on the grinder,

but that, too, loads up quickly and would require DOZENS of discs. We’ll

see how the 6” DA works tomorrow. And yes, JJ and I work well together.

10/7/09

John and I continued today stripping the hood using a combination of a

6” DA, long board sander, and a Scotchbrite pad on the grinder. The

latter was the most effective. We also used some small air-powered

die-grinders and a wire wheel. We have the top and part of the underside

done. Tomorrow should see the whole hood ready for some primer.

Meanwhile, I spent my most of my time in the trunk doing some grinding

and bondo work. I have made about a dozen passes over the trunk pan

seams and the repair areas. I am obviously not making up large batches.

It is looking pretty good now, and I’ll shoot some pix tomorrow before

and after the primer goes on both areas. I spent about $100 today on

bondo hardener and sandpapers for the long board and DA. JJ and I will

also have to address the rear quarters and make some patch panels BEFORE

we but out the old stuff, of course.

We looked at the interior, and the front door panels (metal) look

perfect, and are already primered. We will probably have a hard day of

work in there. The headliner area will be the killer, of course. We also

found a couple of very small holes in the floor pan, which I will

address in the next few days. I will replace the driveshaft tunnel a

little later, once the trans mounts are done.

John is going to bring over his mini-sandblaster, a gift from Randy, and

we’ll see if it affords us some utility in getting at hard-to-reach

areas.

These are the times of very hard work that do not show obvious and

impressive results, but do add to the overall quality of the build.

Gotta do it.

10/8/09

John picked up some play sand, and it was too large and too wet. We went

to Balboa Brick and got a 100# bag of #60 silica. PERFECT. John has

spent several hours blasting the underside of the hood. This unit will

work very well for getting into the drip rails on the top, around the

doors, and other hard-to-reach areas.

I

have continued smoothing out the trunk area. Almost done. Perhaps one

more pass tomorrow with some minor-flaw filling top coat (actually

concentrated lacquer called Nitro Stan). If I were to wrinkle finish the

area, it would be perfect at this point. I’m just being real anal about

it. It is good practice for doing the rest of the car.

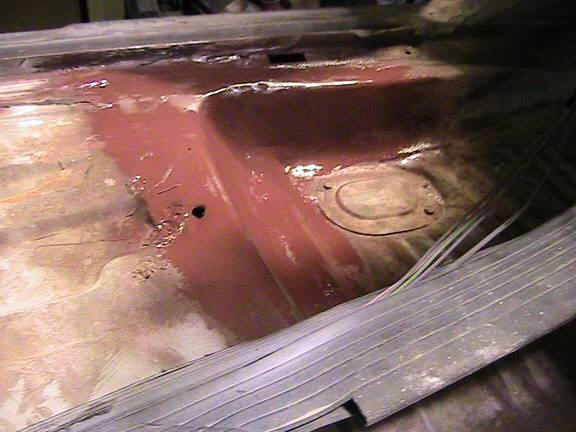

10/10/09

The trunk is essentially done:

I

am now working on filling some holes in the front floor pan. One done,

one to go.

The crossmember under the right side was rotted away, so that got three

pieces of metal welded in to restore that, and some bondo and primer to

maintain a real clean look.

John and I got the windshield out. It is tough removing trim without

damaging it, particularly if we don’t know if it is screwed or clipped

in. Turns out the front window perimeter trim is screwed to the body.

The side pieces were not. We got the window out, dumpsterized, and the

trim removed. John then cleaned the sealing surfaces. They look good,

but we’ll put one more pass with a wire wheel and some lacquer thinner

before shooting some primer there.

John also took the cowl piece (a ZILLION slots) and sandblasted it both

sides. It is PERFECT, and looks brand new. The little sandblaster of his

is working out to be a real gem.

I

spread the word about the HEMI-Cayne at both Bob’s last night. A guy

named Jerry, who had a couple of 58 impalas, and has been here, may come

over to look at the other Biscayne (409) project.

The driver’s side repair is done, and the metal work and welding were

excellent. I covered it with bondo anyway to smooth out the floor.

10/11/09

I

did the two front floors finishing, and primered the right rear floor

pan and the right front pan:

John returns tomorrow and we’ll hit the other sides or perhaps attack

the underside of the top and work down to the floor over there. I need

to get some sanding discs for the little air grinder.

10/12/09

What we did today instead was sandblast all the exterior tough places.

We removed the rear window (again, how would one know if there are

screws in the trim?), and got it out unharmed (both glass and trim). I

have not cleaned it yet, so I don’t know if it is usable. I do have a

boxed replacement for both front and rear glass (used, but purportedly

very good).

We burned through a nozzle on the blaster, got another from Baida, and

John did a great job. While John was finishing blasting, I blew out and

hosed down the garage. We cleaned the car and driveway (LOTS of

vacuuming), and rolled the car into the front bay. I sprayed all the

recessed glass areas, around the windows, etc. with satin black primer.

We’ll roll it out again tomorrow, get some more sand, and start on the

interior.

10/13/09

We did NOT roll the car out today, as it rained. We instead worked on

using the long-board air sander, got a bunch of other sanding discs and

supplies, and bought another KILLER grinder at ACA (A Cut Above), and we

went to work just sanding inside, vacuuming, etc. The garage has gotten

cleaner every time I blow it out, so we’re working on avoiding wholesale

dirt production.

JJ sanded all the areas I primed, Randy came by and gave us more good

suggestions, and JJ and I sanded until late afternoon. I did the

passenger side of the top of the car, and it is ready for primer. JJ did

the shoulders on both sides (from the windows down to the first change

on the doors and fenders) by hand, and those areas look great. I got

more primer today, and he and I will prime those areas in the morning.

While we are waiting for those areas to dry, we can do a lot of garage

organizing. We might go ahead and do the remainder of the driver’s side

of the top, and a few other areas first, THEN prime those areas.

|